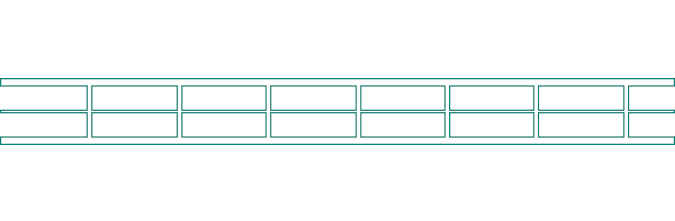

| |

Thickness |

Weight (lb/ft2) |

Weight (g/m2) |

Light Transmission Clear |

Sound Reduction Index dB |

Cold Forming Radius (min. radius) |

Colors |

|

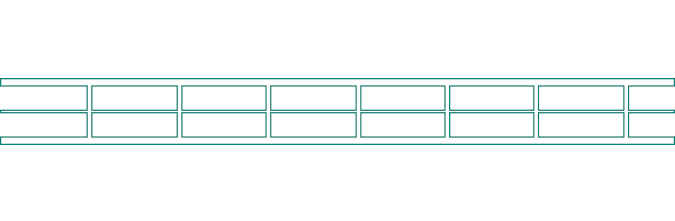

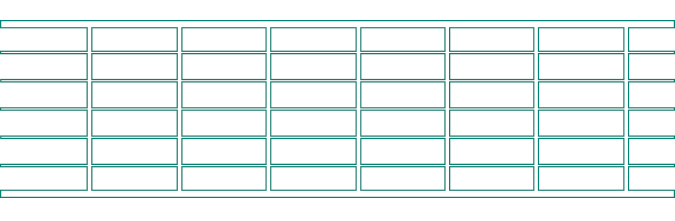

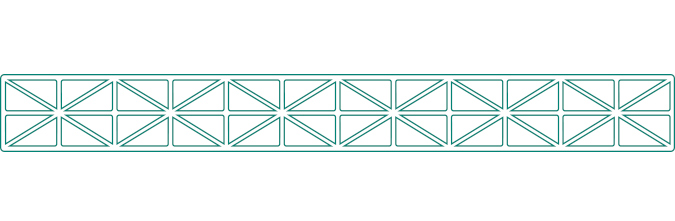

3W

Macrofort

|

10mm |

0.63 |

3100 |

74 |

21 |

66.9 |

Clear (0010)

Bronze (0024)

Opal (0037)

Opal (0299)

Green (0422)

Blue (0522)

Grey (0650)

White (0310)

Opale (0309)

White/Grey (0691) |

|

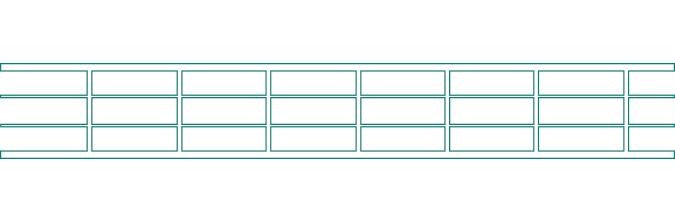

4W

|

6mm |

0.26 |

1300 |

70 |

15 |

47.2 |

| 8mm |

0.31 |

1500 |

70 |

16 |

63.0 |

| 10mm |

0.36 |

1750 |

69 |

19 |

78.7 |

|

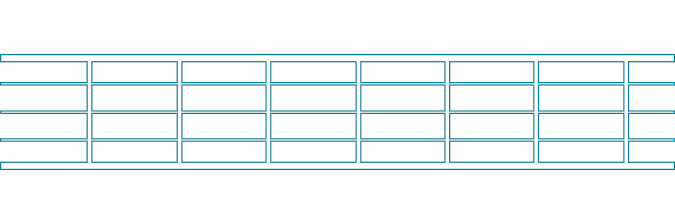

5W

|

16mm |

0.55 |

2700 |

66 |

21 |

94.5 |

| 20mm |

0.61 |

3000 |

60 |

23 |

118.1 |

| 25mm |

0.67 |

3300 |

60 |

23 |

147.6 |

|

5WX

X Structure

|

16mm |

0.51 |

2500 |

62 |

21 |

94.5 |

|

7W

|

16mm |

0.51 |

2500 |

55 |

21 |

94.5 |

| 20mm |

0.63 |

3100 |

54 |

23 |

118.1 |

| 25mm |

0.67 |

3300 |

50 |

23 |

147.6 |

|

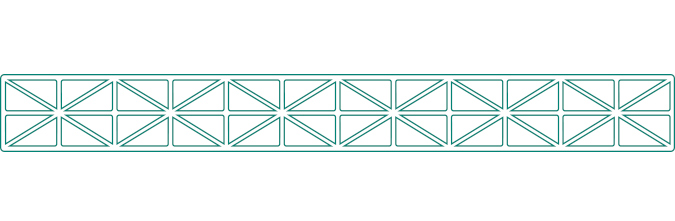

10W

|

50mm |

1.02 |

5000 |

N/A |

24 |

NOT RECOMMENDED |

| 55mm |

1.06 |

5200 |

36 |

24 |

| 60mm |

1.23 |

6000 |

31 |

25 |

|

10W

X Structure

|

16mm |

0.57 |

2800 |

48 |

21 |

157.4 |

FOR OPAL |

| 113.3 |

| 20mm |

0.65 |

3200 |

41 |

23 |

196.8 |

141.7 |

| 25mm |

0.69 |

3400 |

38 |

23 |

246.1 |

177.1 |

| 32mm |

0.76 |

3700 |

34 |

23 |

314.9 |

226.7 |

| 35mm |

0.78 |

3800 |

32 |

23 |

344.4 |

248.0 |

| 40mm |

0.88 |

4300 |

28 |

23 |

393.7 |

283.4 |

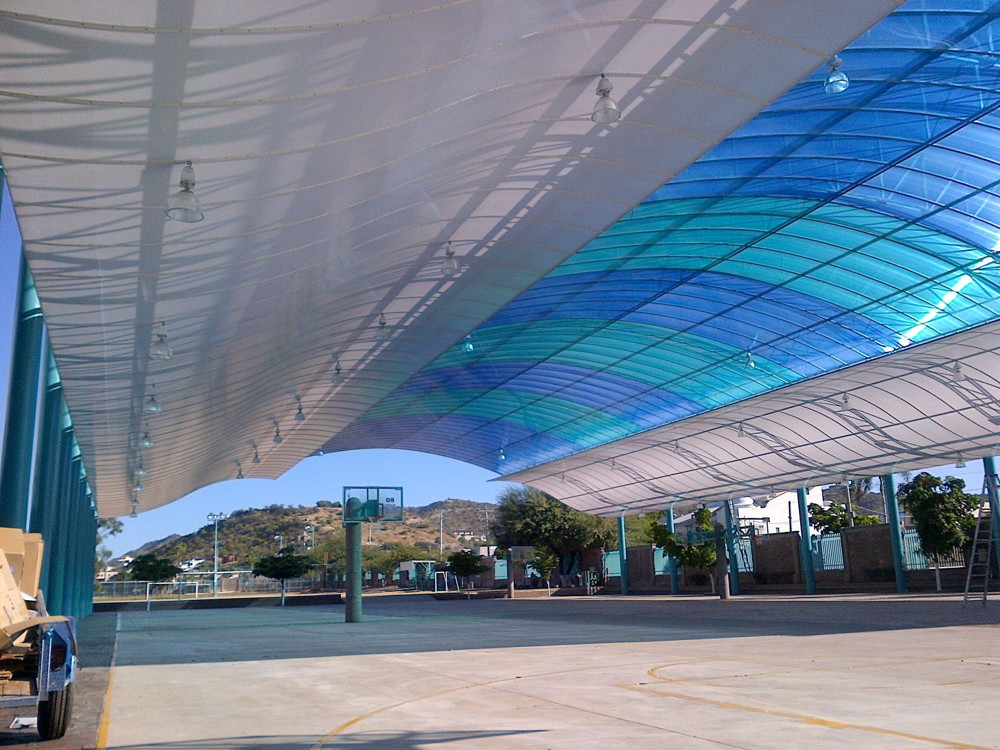

MACROLUX® MULTIWALL sheets are manufactured in a wide range of versions and they can fit every

project requisite.

| Special Layers |

| Base version |

LL |

UV protected sheets on 1 side. |

| Available versions for the

Solar Control |

HS |

Reflective sheets with a special surface

treatment that allow to effectively reflect

much of the infrared radiation. |

| ATHERMIC |

Dual color sheets that serve the dual

purpose of reducing heat gain inside the

room and shielding the interior to stop

too much light getting in. |

| IR |

Translucent sheets that combines the

absorbing and reflective properties,

reducing the amount of infrared

radiation, responsible of the “green

house effect”. |

| Additional “UV”

Treatments |

NO UV |

Sheets not protected from the effect of

UV rays. |

| XL |

UV protected sheets on 2 sides |

| PLUS |

Sheets with increate, extra strong

protection from UV rays. |

| Other

Treatments |

MINDEW |

Sheets with treatment on the inside

to stop condensation dripping off the

surface and falling into the room. |

| ANTISTATIC |

Sheets with treatment which reduces

the static electricity surface, minimizing

the effect of attracting dust. |

| Particular

Colors |

BICOLOR |

Sheets made with a special method to

produce one color on the inside and a

different color on the outside. |

| Sheet |

Section |

Solar Control |

| 4W |

Thicknesses: 6 - 10 mm |

HS | IR | AT |

| 3W |

Thickness: 16 mm |

|

| 5W |

Thicknesses: 16 -25 mm |

HS | IR | AT |

| 5X |

Thickness: 16 mm |

IR | AT |

| 7W |

Thicknesses: 16 -20 - 25 mm |

HS | IR |

| 10X |

Thicknesses: 16 -20 - 25 - 32 mm |

HS | IR | AT |

| 10W |

Thicknesses: 40 - 50 - 55 - 60 mm |

|

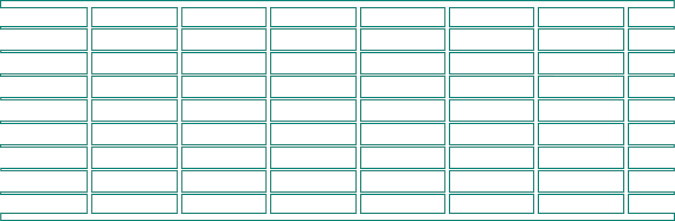

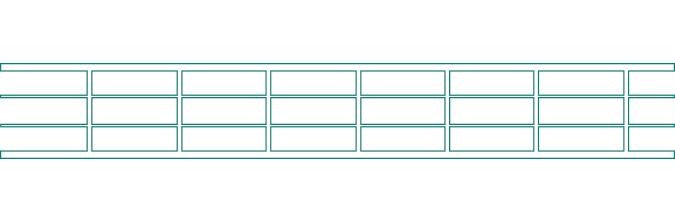

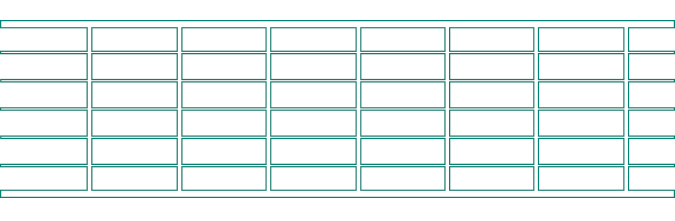

| Physical specification |

| SHEET THICKNESS |

10mm |

6mm |

8mm |

10mm |

16mm |

20mm |

25mm |

16mm |

16mm |

20mm |

25mm |

50mm |

55mm |

60mm |

16mm |

20mm |

25mm |

32mm |

35mm |

40mm |

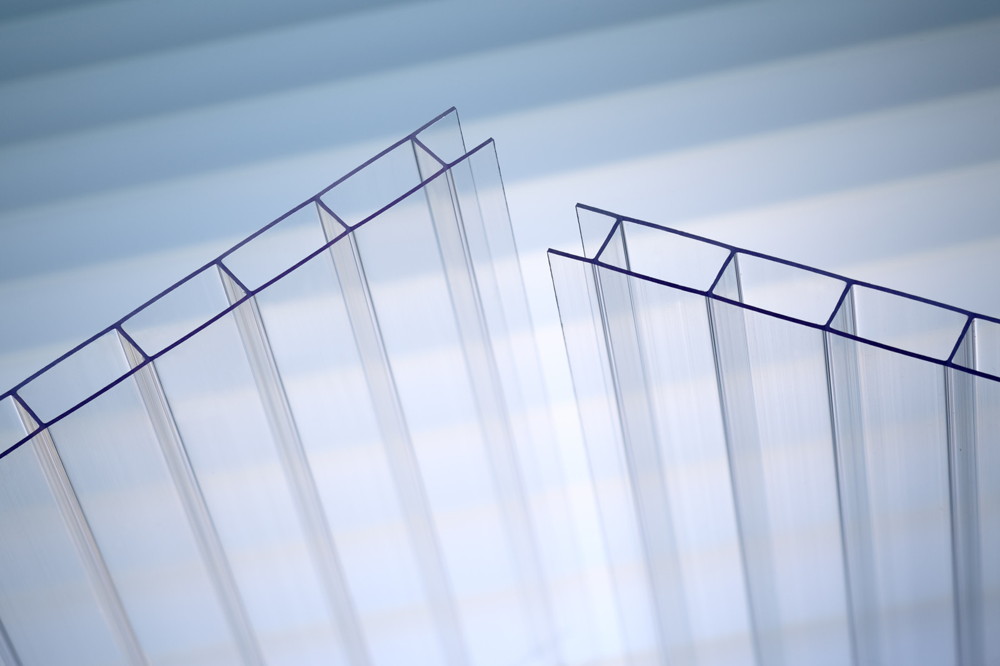

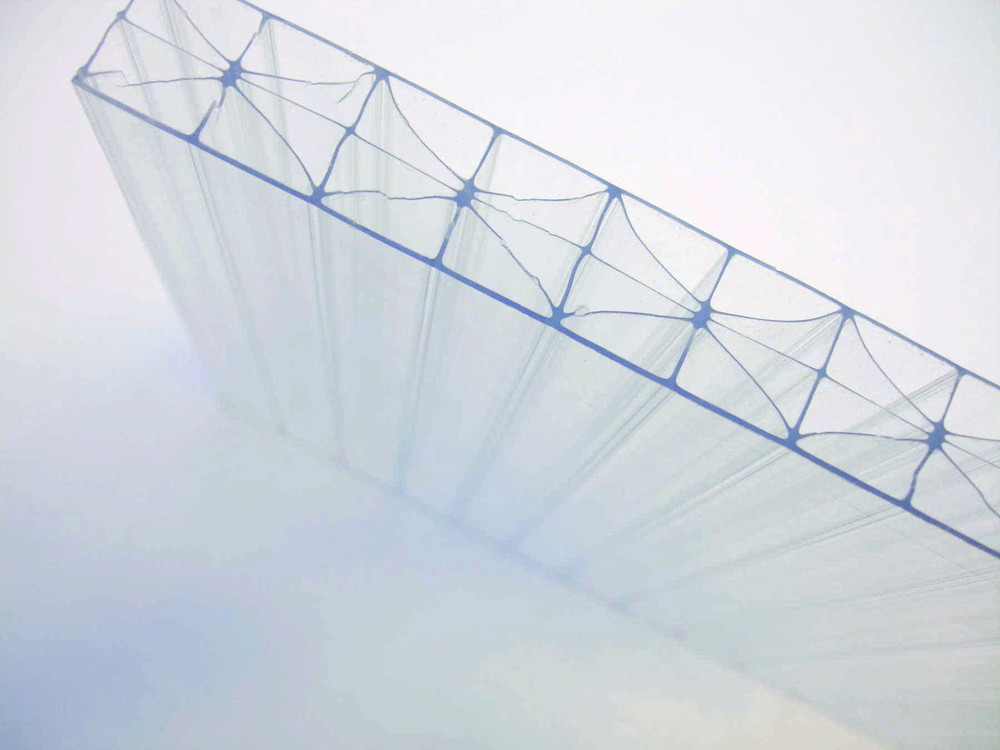

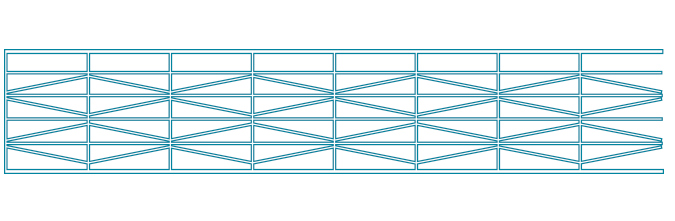

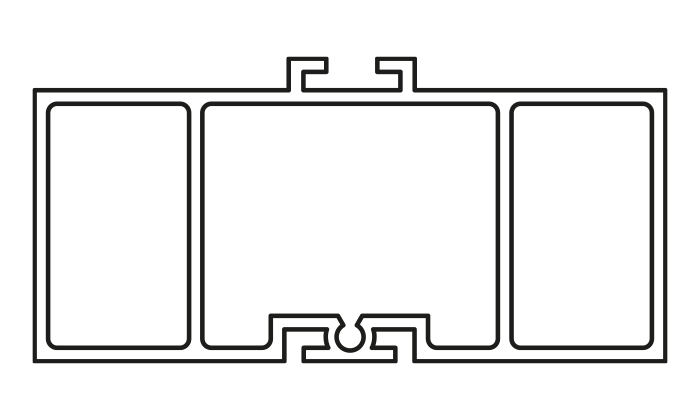

| Structure |

3W Macrofort |

4W |

5W |

5WX X Structure |

7W |

10W |

10WX X Structure |

| Weight (lb/ft2) |

0.63 |

0.26 |

0.31 |

0.36 |

0.55 |

0.61 |

0.67 |

0.51 |

0.51 |

0.63 |

0.67 |

1.02 |

1.06 |

1.23 |

0.57 |

0.65 |

0.69 |

0.76 |

0.78 |

0.88 |

| Weight (g/m2) |

3100 |

1300 |

1500 |

1750 |

2700 |

3000 |

3300 |

2500 |

2500 |

3100 |

3300 |

5000 |

5200 |

6000 |

2800 |

3200 |

3400 |

3700 |

3800 |

4300 |

| Light transmission %

Clear (0010) |

74 |

70 |

70 |

69 |

66 |

60 |

60 |

62 |

55 |

54 |

50 |

- |

36 |

31 |

48 |

41 |

38 |

34 |

32 |

28 |

| Light transmission %

Bronze (0024) |

- |

- |

- |

- |

25 |

20 |

20 |

20 |

- |

- |

- |

- |

- |

- |

- |

- |

18 |

- |

- |

- |

| Light transmission %

Opal (0037) |

66 |

- |

- |

- |

46 |

40 |

35 |

35 |

31 |

27 |

24 |

- |

- |

- |

28 |

26 |

17 |

10 |

9 |

7 |

| Light transmission %

Blue (0522) |

- |

- |

- |

- |

30 |

25 |

25 |

25 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

13 |

- |

- |

| Light transmission %

Gray (0650) |

- |

- |

- |

- |

25 |

20 |

20 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| Light transmission %

White (0310) |

- |

- |

- |

- |

10 |

10 |

10 |

8 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| Light transmission %

Opale (0309) |

- |

- |

- |

- |

50 |

50 |

35 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

33 |

- |

- |

| Std. Widths (in) |

82.67” (For information regarding other widths, please contact Stabilit Suisse |

| Lengths (ft) |

4’ up to 39’ |

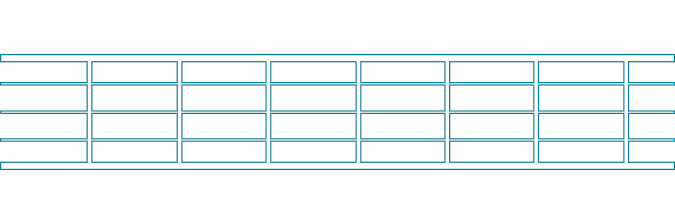

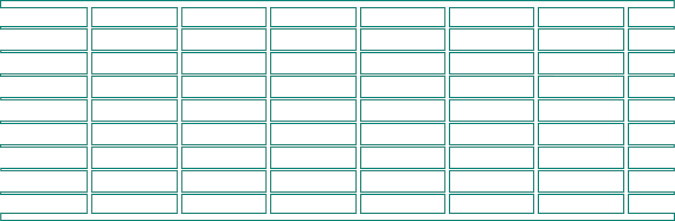

| SHEET THICKNESS |

Unit |

10mm |

6mm |

8mm |

10mm |

16mm |

20mm |

25mm |

16mm |

16mm |

20mm |

25mm |

50mm |

55mm |

60mm |

16mm |

20mm |

25mm |

32mm |

35mm |

40mm |

| Structure |

|

3W Macrofort |

4W |

5W |

5WX X Structure |

7W |

10W |

10WX X Structure |

| Thermal Insulation Btu/hr - ft2 ºF(ASTM C976/90) |

U Value |

0.48 |

0.55 |

0.49 |

0.44 |

0.33 |

0.30 |

0.28 |

0.35 |

0.32 |

0.28 |

0.25 |

0.16 |

0.14 |

0.14 |

0.28 |

0.26 |

0.23 |

0.18 |

0.19 |

0.18 |

| R Value |

2.08 |

1.82 |

2.04 |

2.27 |

3.03 |

3.33 |

3.57 |

2.86 |

3.12 |

3.57 |

4.00 |

6.25 |

7.14 |

7.14 |

3.57 |

3.85 |

4.35 |

5.56 |

5.26 |

5.56 |

| Cold forming radius (min. radius) |

Inch |

66.9 |

47.2 |

63.0 |

78.7 |

94.5 |

118.1 |

147.6 |

94.5 |

94.5 |

118.1 |

147.6 |

NOT RECOMMENDED |

157.4 |

196.8 |

246.1 |

314.9 |

344.4 |

393.7 |

| For Opal |

| 113.1 |

141.7 |

177.1 |

226.7 |

248.0 |

283.4 |

| Heat expansion coefficient |

Inch/ftºF |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

3.6 x 10-5 |

| Max. permanent service temperature w/o load |

ºF |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

248 |

| Possible expansion due to heat and moisture |

in/ft |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

0.036 |

| Weighted sound reduction index |

dB |

21 |

15 |

16 |

19 |

21 |

23 |

23 |

21 |

21 |

23 |

23 |

24 |

24 |

25 |

21 |

23 |

23 |

23 |

23 |

23 |

Heat Expansion

Macrolux Multiwall PC sheet has a higher heat expansion coefficient than standard construction materials

such as glass, steel and aluminum. Specific clearance between the sheet and the structural frame has to be

calculated in order to ensure proper installation.

| Material |

Heat Expansion Coefficient (inch/ftºF) |

| Macrolux Multiwall |

3.6x10-5 |

| Glass |

5x10-5 |

| Steel |

8x10-5 |

| Aluminum |

1.6x10-5 |

Fire Behavior

Macrolux Multiwall PC sheet is produced using world class high-quality polycarbonate resin. It does not

burn easily and has been defined as a self-extinguishable material by international standards in different

countries.

| ASTM |

CLASSIFICATK |

| ASTM E84-01 |

ClassA (NFPA); Class (UBC) |

| ASTM D635-74 |

Class CC1 |

| ASTM D2843-93 |

Low Smoke Density (UBC standard No. 26-5) |

| ASTM D1929-68 |

Self Ignition Temperature greater than 650ºF |

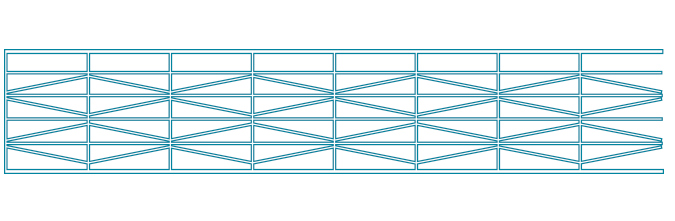

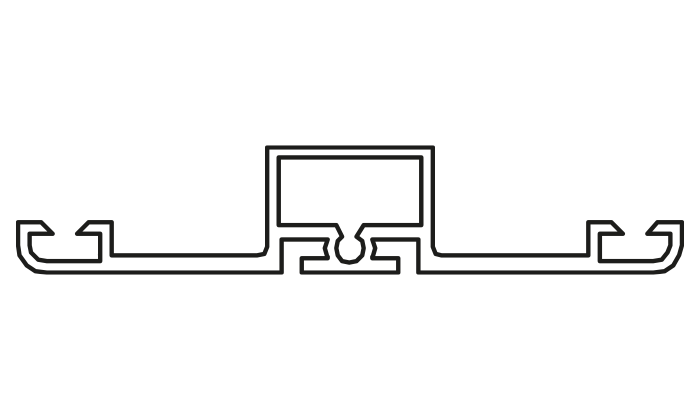

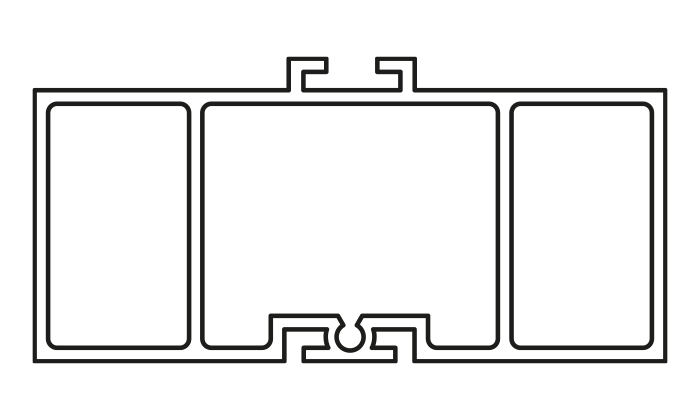

ACCESSORY

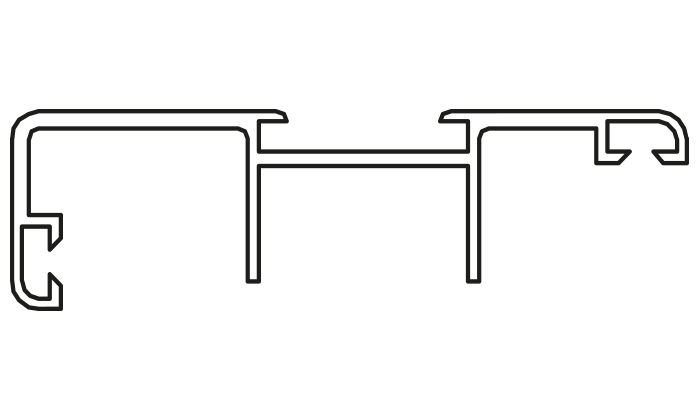

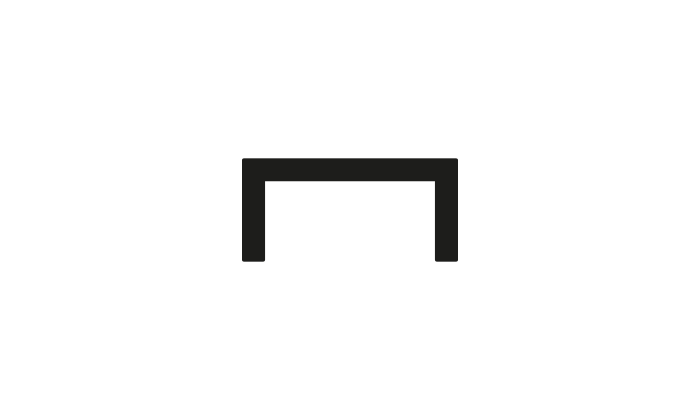

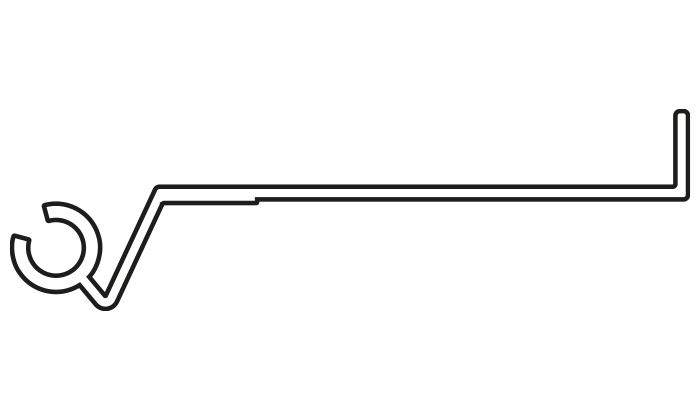

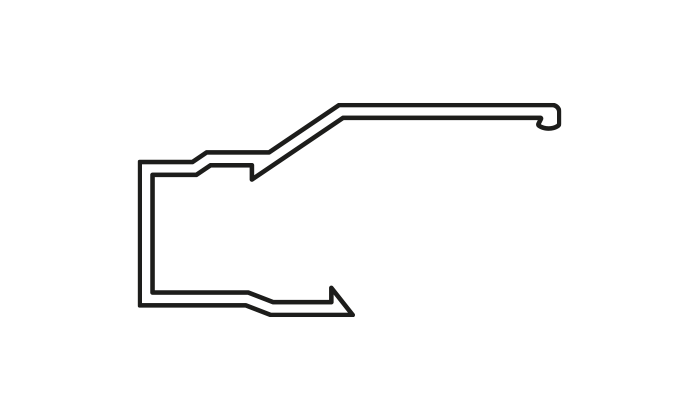

[SCHEME]

|

DIM

(mm) |

TECHNICAL DESIGN |

PC U 6 mm profile

(Cod. M633)

|

2100 / 6000 |

|

PC U 10 mm profile

(Cod. M634)

|

2100 / 6000 |

|

PC U 16 mm profile

(Cod. M635)

|

2100 / 6000 |

|

PC H 6 mm profile (UV protected)

(Cod. M430)

|

6000 |

|

PC H 10 mm profile (UV protected)

(Cod. M431)

|

6000 |

|

PC H 16 mm profile (UV protected)

(Cod. M432)

|

6000 |

|

PC ridge profile 6 mm (UV protected)

(Cod. M448)

|

6000 |

|

PC ridge profile 10 mm (UV protected)

(Cod. M449)

|

6000 |

|

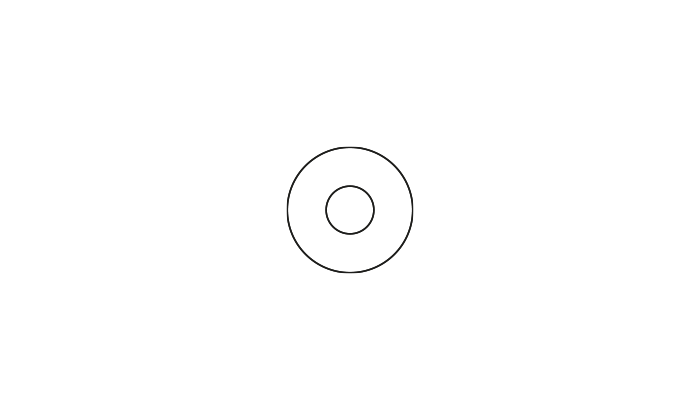

Washer 6 mm with seal

(Cod. M960)

|

---

|

|

Washer 10 mmwith seal

(Cod. M961)

|

---

|

|

Washer 16 mm with seal

(Cod. M952)

|

---

|

|

Aluminium tape (50 m roll)

(Cod. M967)

|

H = 25 mm |

|

Aluminium tape (50 m roll)

(Cod. M965)

|

H = 38 mm |

|

Aluminium tape (50 m roll)

(Cod. M957)

|

H = 50 mm |

|

Aluminium tape (50 m roll)

(Cod. M966)

|

H = 70 mm |

|

Aluminium breather tape (50 m roll)

(Cod. M968)

|

H = 38 mm |

|

Aluminium breather tape (50 m roll)

(Cod. M969)

|

H = 50 mm |

|

Aluminium breather tape (50 m roll)

(Cod. M970)

|

H = 70 mm |

|

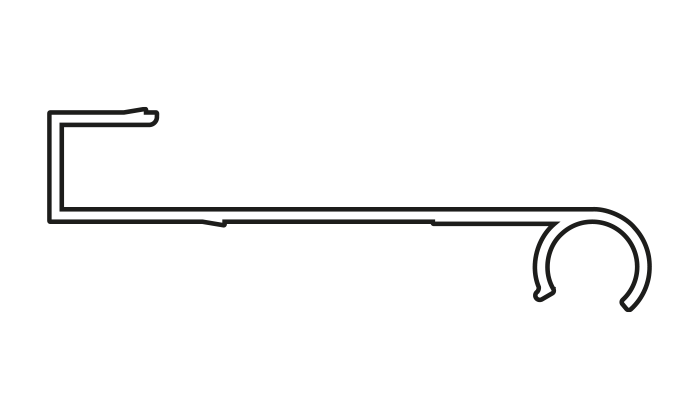

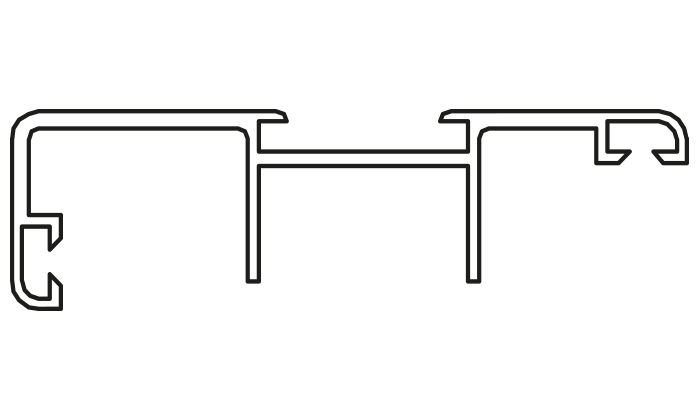

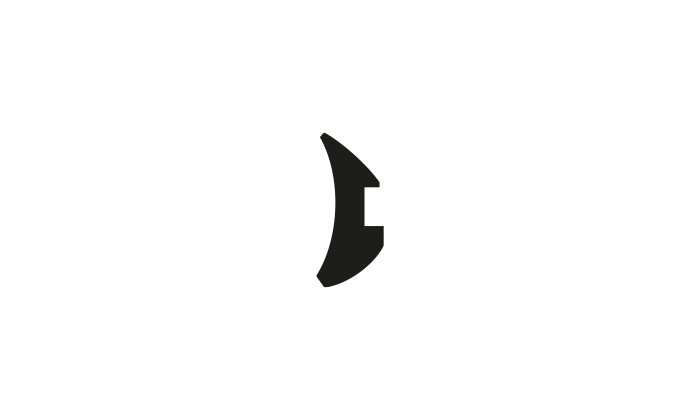

ACCESSORY

[SCHEME]

|

DIM

(mm) |

TECHNICAL DESIGN |

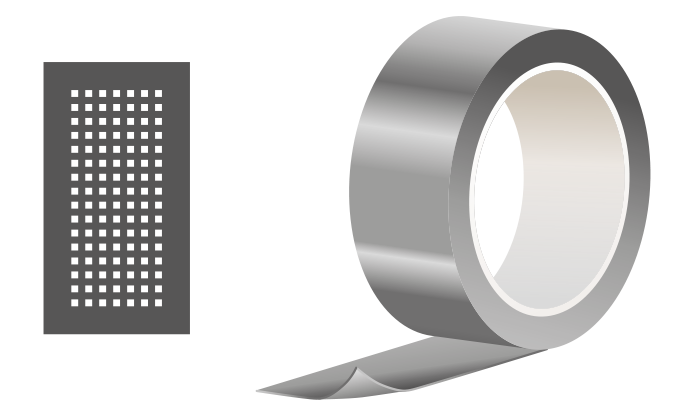

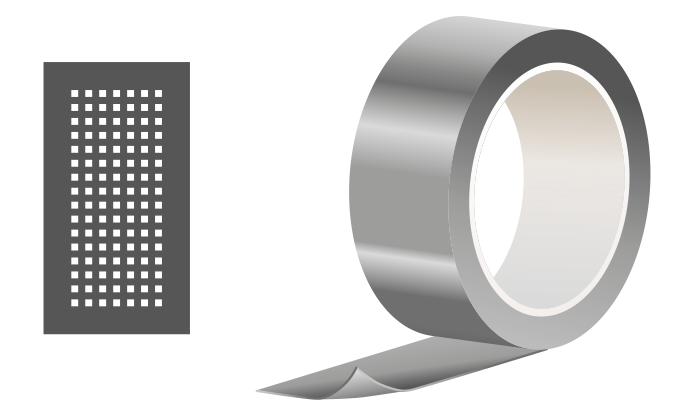

Perforated aluminium tape (50 m roll)

(Cod. MXA8)

|

H = 90 mm |

|

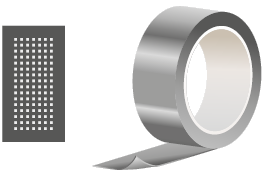

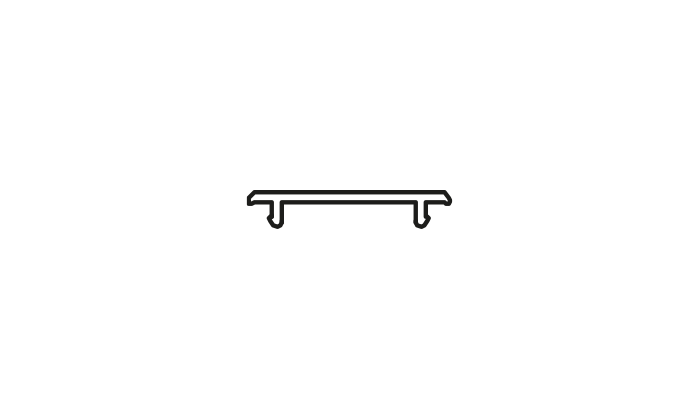

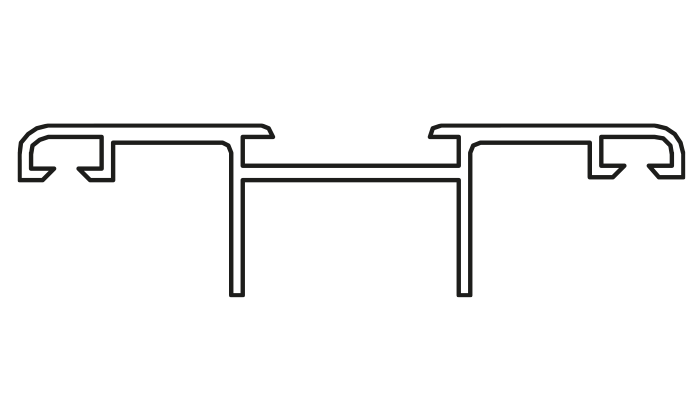

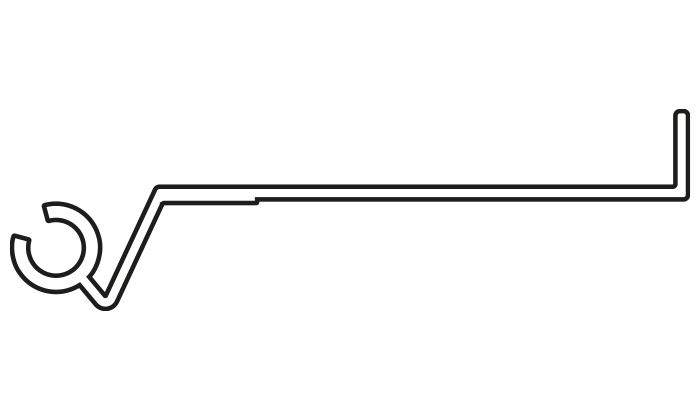

Upper aluminium joining profile

(Cod. M9S7)

[ B ]

|

6000 |

|

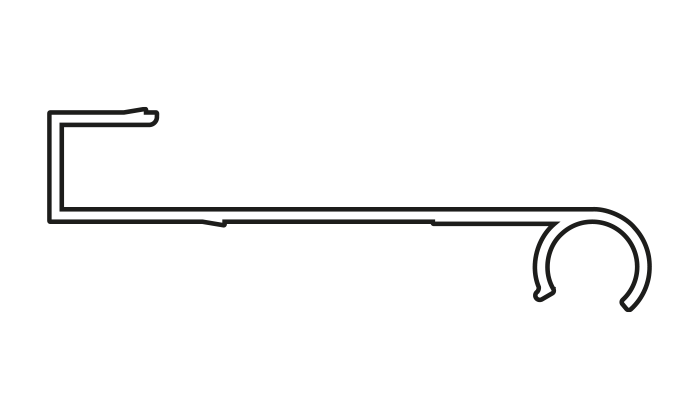

Lower aluminium joining profile

(Cod. M9S8)

[ B ]

|

6000 |

|

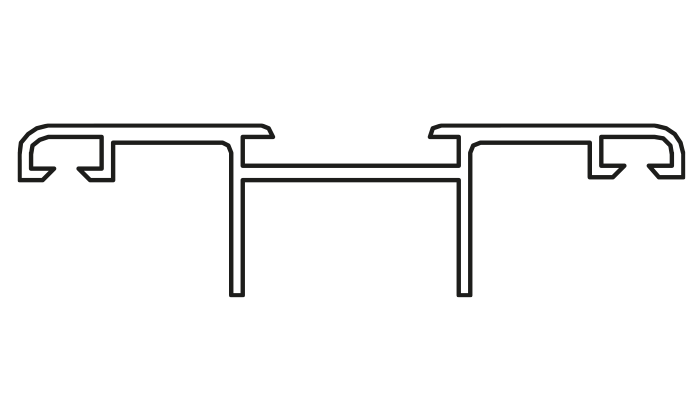

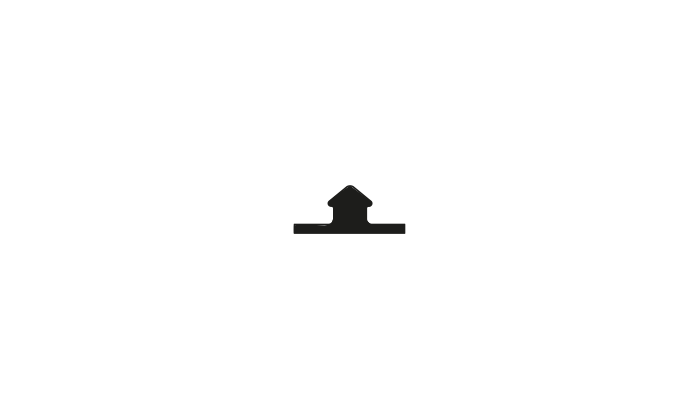

Aluminium upper head profile

(Cod. M9S9)

[ A ]

|

6000 |

|

Aluminium lower head profile

(Cod. M9T0)

[ A ]

|

6000 |

|

Aluminium cap profile

(Cod. M9T1)

[ A ]

[ B ]

|

6000 |

|

1 mm EPDM gasket

(Cod. M9S3)

[ A ]

[ B ]

|

---

|

|

3 mm EPDM gasket

(Cod. M9S5)

[ A ]

[ B ]

|

---

|

|

EPDM thermal-break seal

(Cod. M9T5)

[ A ]

[ B ]

|

---

|

|

Rubber seal

(Cod. M9Z9)

[ A ]

[ B ]

|

---

|

|

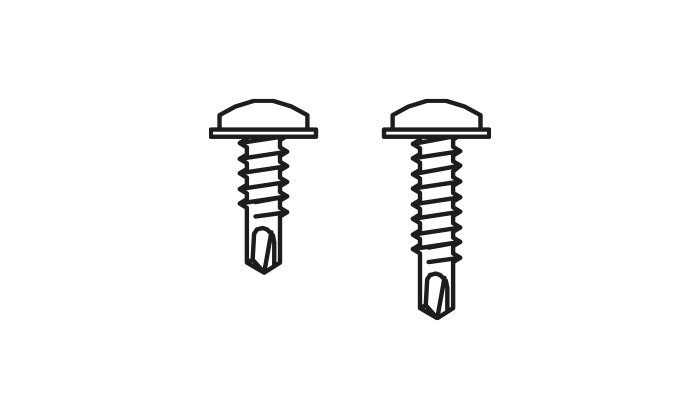

Screws

(Cod. M9T3)

(Cod. M9T4)

[ A ]

[ B ]

|

4.2 x 13; 4.2 x 19 |

|

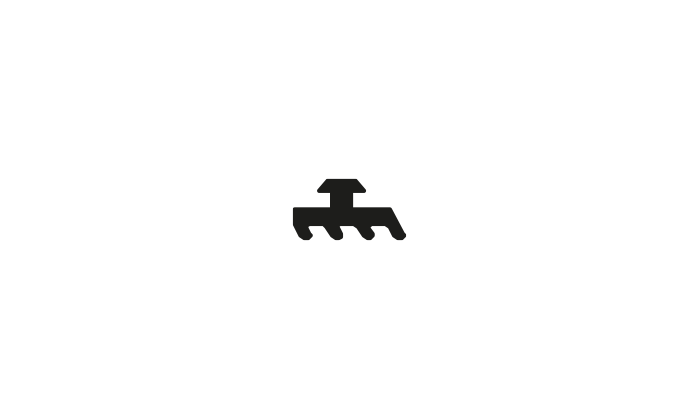

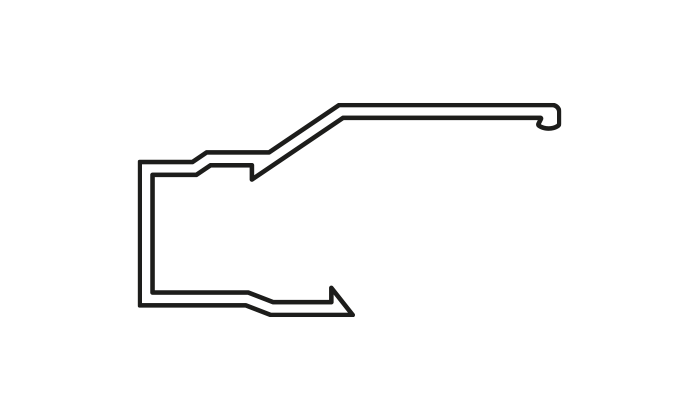

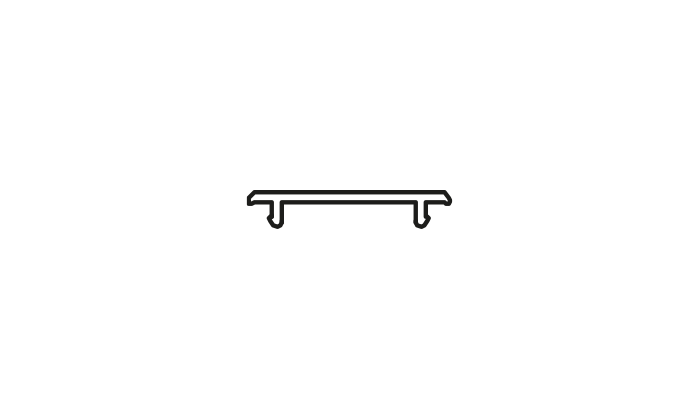

Aluminium strengthening profile

(Cod. M9T2)

|

6000 |

|

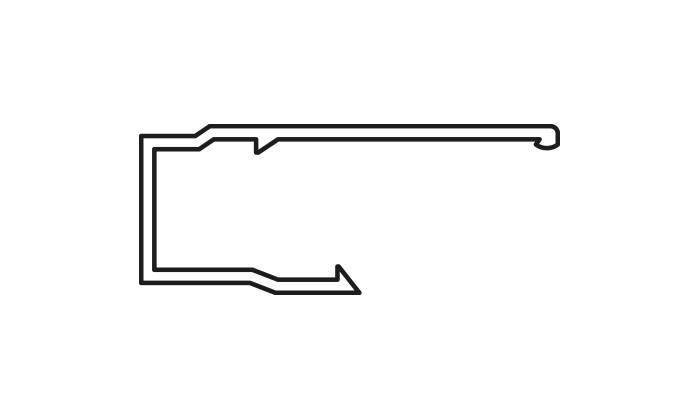

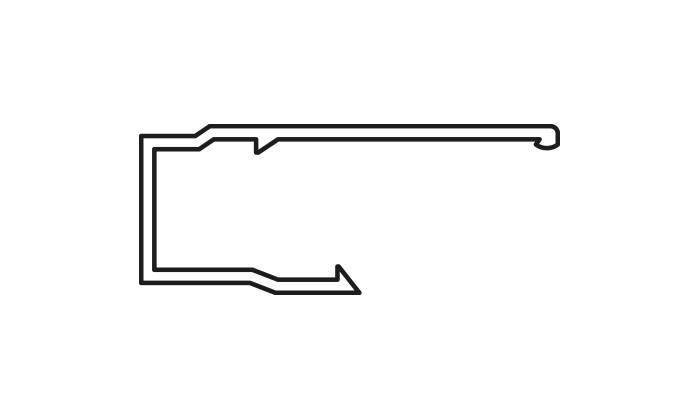

Aluminium fixed sill profile

(Cod. M9R6)

[ C ]

|

6500 |

|

Aluminium revolving sill profile

(Cod. M9R7)

[ C ]

|

6500 |

|

10 mm aluminium panel stop

(Cod. M9R4)

[ C ]

|

5700 |

|

16 mm aluminium panel stop

(Cod. M9R5)

[ C ]

|

5700 |

|

EPDM gasket

(Cod. M926)

[ C ]

|

---

|

|

- In order to avoid condensation in the sheet cells and sheet deterioration, always place the sheet with the

cells in the vertical direction.

- Always store the sheets in horizontal position, never against the floor. Apply aluminum tape to seal the

cells after cutting the sheet. Do not walk over the sheets.

- Do not apply direct load on the sheet with foot or knee. Use wood platforms or supports to spread out the

pressure during installation.

- Remove IIV protecting masking only and right after installation; never before and never after hours of being

installed.

- Macrolux® PC sheet can be cut to size using tools for standard materials such as cutters and saws. However,

it is recommended the use of a table with fixed

- knives for a cleaner cut.

- It is not recommended to drill holes in the sheet. Rather than this, the recommendation is the use of

aluminum or polycarbonate profiles to fix the sheets to the structure.

- Never use PVC profiles when installing Macrolux®PC sheets.

Cleaning and Maintenance

- For general cleaning it is recommended to use a non-abrasive, solvent free neutral soap with water.

- Rinse with high-pressure washer-Use a soft cloth or sponge to loosen any remaining of dirt and grime. Never

use abrasive cleaners or brushes. Do not scrub the sheet surface.

- Never clean with gasoline, benzene or acetone.

Bonding Adhesives

It is recommended to use silicone based sealant such as Dow Corning- 791 or equivalent.