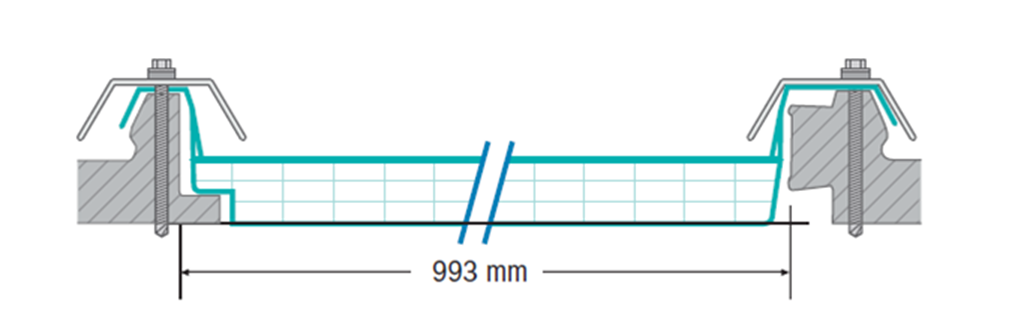

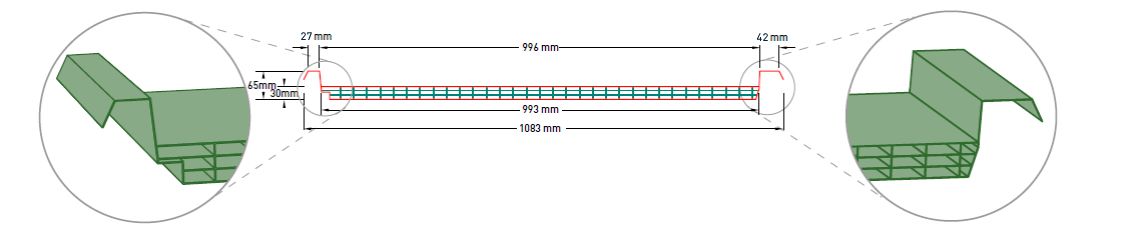

Macrolux Easyroof 30/4W should be made from ridge to channel and with minimum slope of 7%.

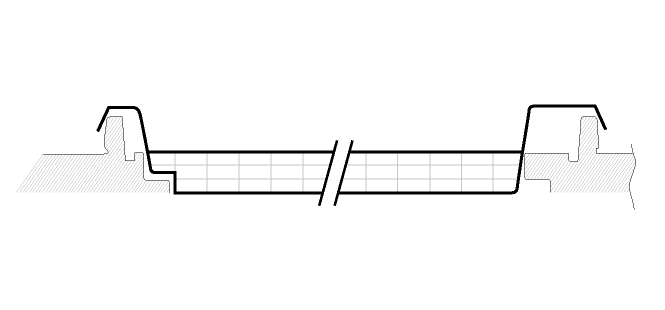

In order that the metallic elements do not scratch the inner part of the Macrolux Easyroof 30/4W, it is recommended to place a neoprene or E.P.D.M. where the sheet is supported and sealed.

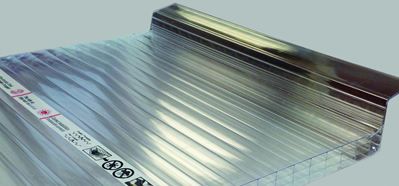

Macrolux Easyroof 30/4W is protected with a film on its outer side with the objective of protect the material during its storage, transportation and installation. Because of the wings’ structure, it is not possible to place it upside down anyway, this film shows that this side is the one with UV protection and some management and installation tips, consider that it should be immediately removed once that installation is finished, on the contrary, it will remain attached to the sheet. When necessary, make a seal on the joints, assure the compatibility of the polycarbonate with the sealant (it is recommended cured neutral sealant alcohol based).

It is essential to cover the cells in order to avoid the entrance of dust inside the sheet. It is recommended to place aluminum tape and window tape on the external: flat on top and porous on the lower end, this avoids internal condensation. In case of wanting these tapes placed from the manufacture of Macrolux Easyroof 30/4W, please indicate it on your order so that it can be quoted and considered.

During the material manipulation on deck for installation, there should be precautions and do not drag the Macrolux Easyroof 30/4W on the metal cover because it may cause scratches and irreversible damage on the back of the sheet.

Macrolux Easyroof 30/4W can be easily cut with circular saws (with small tooth blades), mechanical or saws for metal with fine tooth (in these cases it is needed to hold the sheet in order to avoid vibrations). It is convenient to eliminate remains of shavings lodged in the cells of the sheet.

Do not step, use for walking nor lean on the Macrolux Easyroof 30/4W during maintenance operations, installation or cleaning.

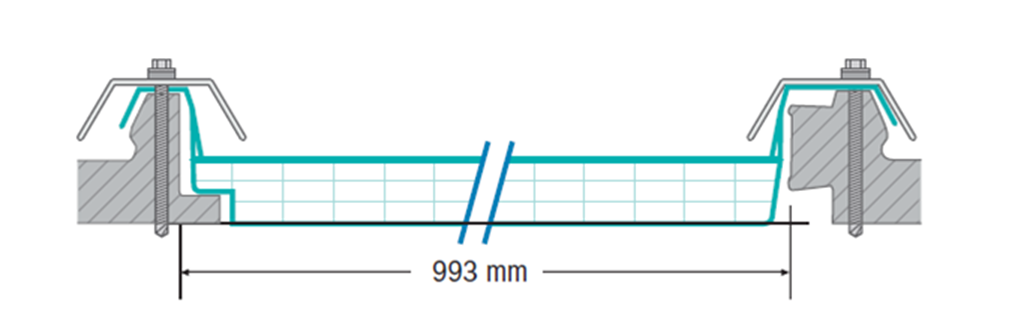

The polycarbonate thermal expansion coefficient is noticeably superior to those of the metallic structures and of other plastic products, so it is essential to foresee systems that allow the free expansion of the sheets. To fix Macrolux Easyroof 30/4W it is needed to make bigger holes on the upper part of the tabs/wings with a diameter bigger that the screw, placing a support beneath the border to avoid vibrations while making the hole.

Once the holes are made and having cut the Macrolux Easyroof 30/4W longitudinally between 2 isolated steel panels, metallic flashing should be placed so that it is screwed on top to fix the Macrolux Easyroof 30/4W border and stays fixed to the border of the sandwich sheet.