Other Products

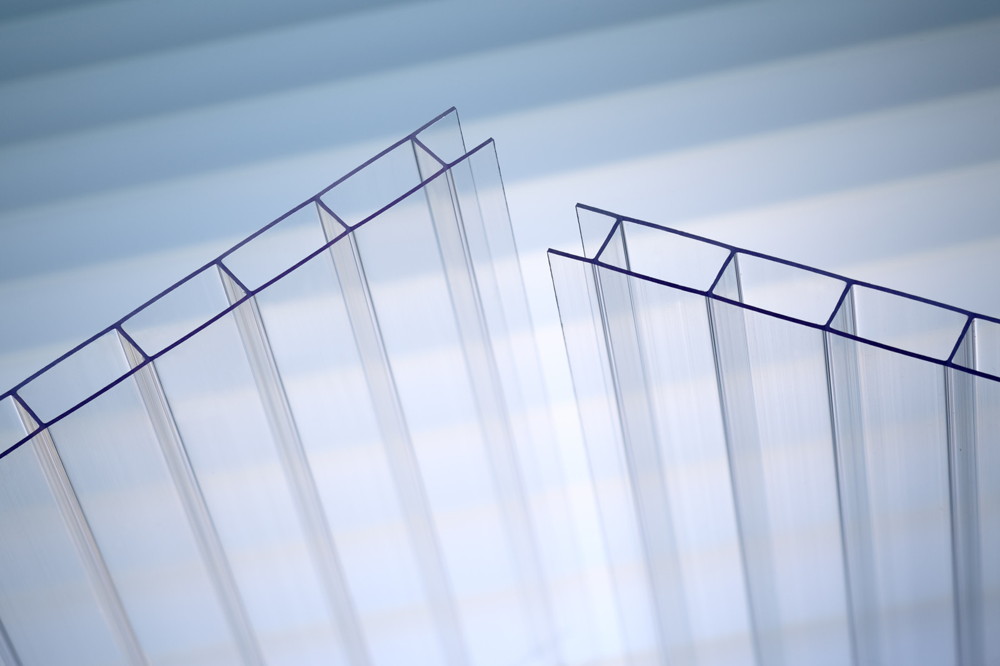

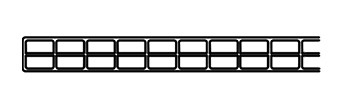

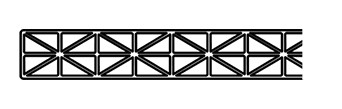

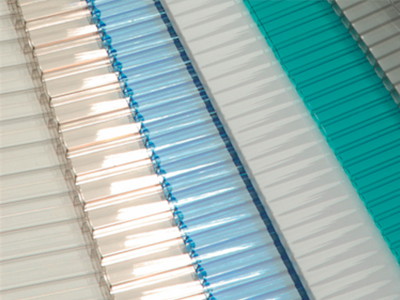

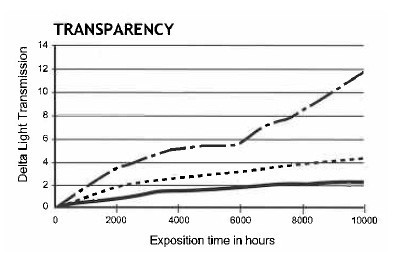

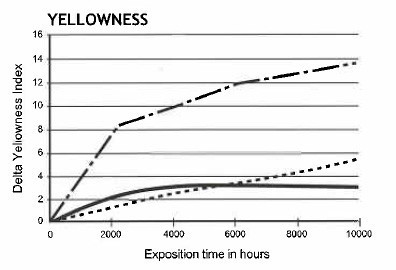

Macrolux Multiwall polycarbonate sheets are an extruded plastic laminate produced with high technology polycarbonate resin. It has a protective layer to counteract weathering effects produced by UV rays.

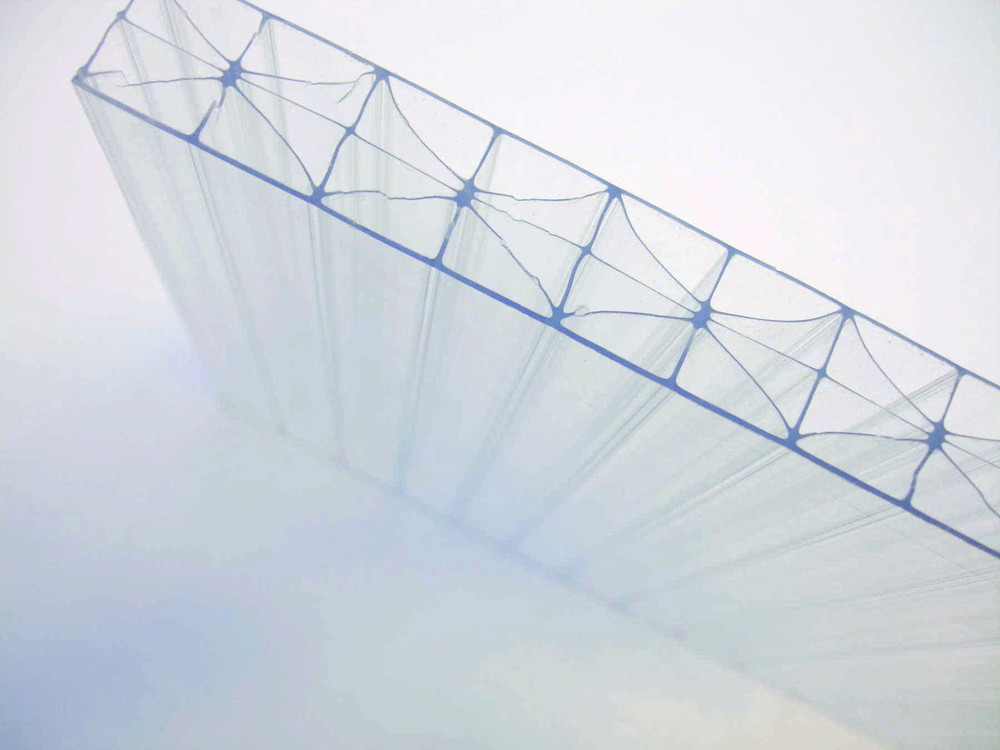

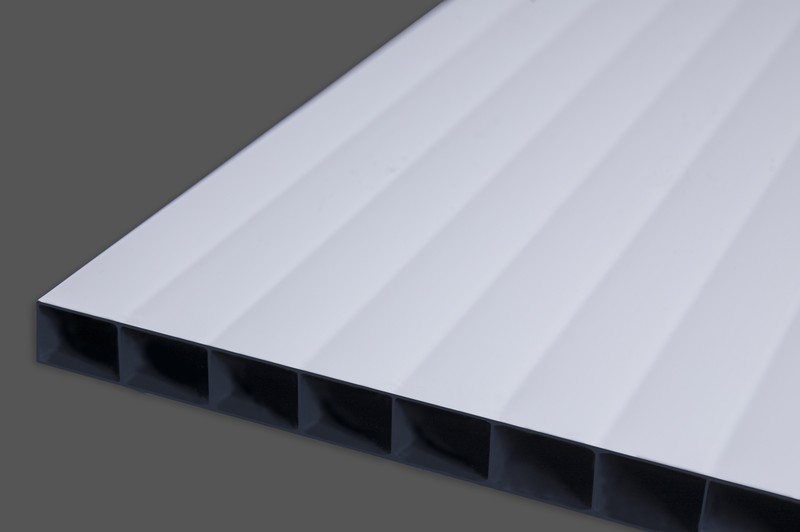

Macrolux Rooflite polycarbonate sheets are a high-performance material for natural lighting indoors or decks. Polycarbonate sheets are made with high technology resin.

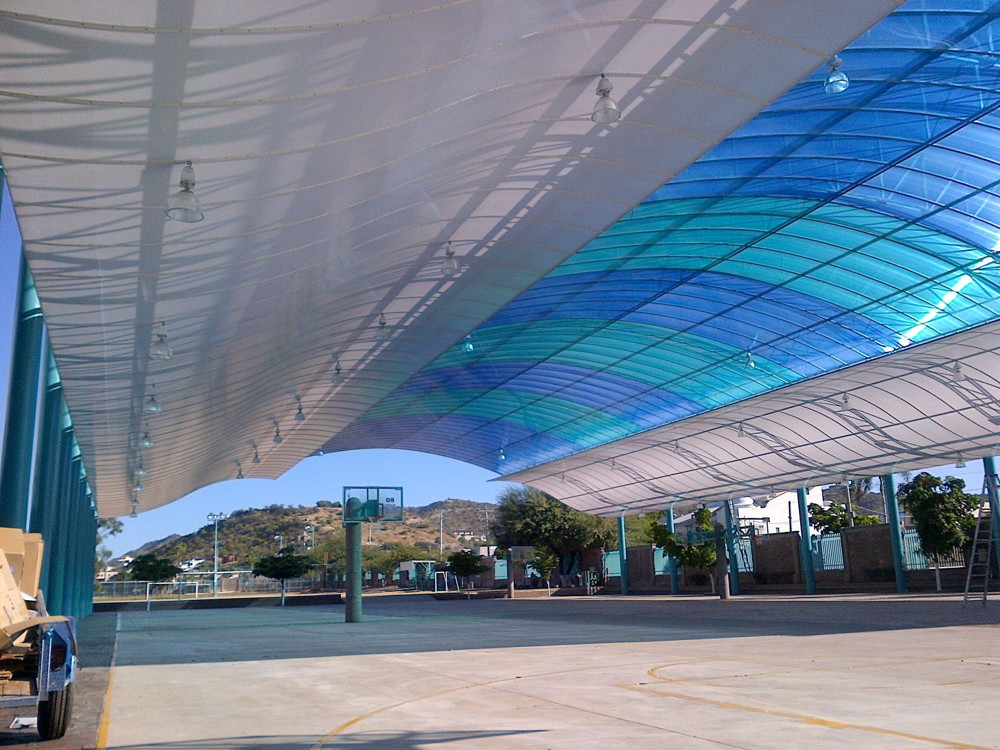

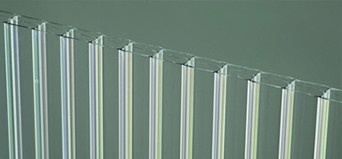

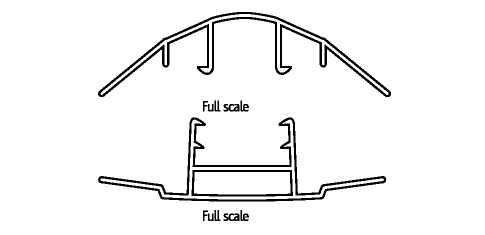

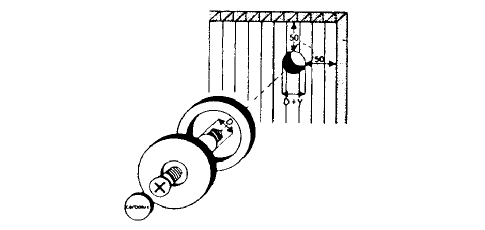

Macrolux polycarbonate specialized systems can be used as trapezoidal sheets, modular locking systems, panels for roofs combined with existing metallic structures and self-supporting solutions.

Macrolux Solid polycarbonate sheets are an excellent option for natural lighting when security and impact resistance are essential. Solid polycarbonate sheets are a very versatile material that can be cut or cold formed when being installed.